Value Delivered

This project was completed in seven months without the interruption of existing production, warehousing, or packaging processes. Shambaugh met the client’s challenging project schedule, utilizing detailed engineering and our in-house, state-of-the-art fabrication shop. This was a fast-track expansion project focused on process control and ammonia refrigeration.

Client Objectives

Nestle needed a 136,000-square-foot addition to produce new “Hot Pocket Toaster Breaks” on a new production line.

Scope of Services

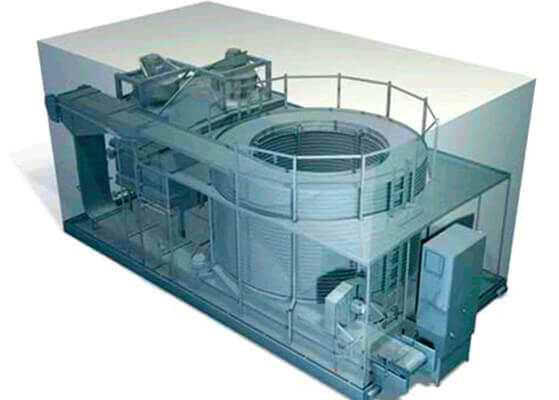

Shambaugh installed a 400-ton spiral freezer with over 1,000 tons of additional compressor capacity enhancements. Our team also designed, prefabricated, and installed all material handling and process control-related systems.

Our team installed the following systems:

- 400-ton spiral freezer

- 700-horsepower booster compressor

- 400-horsepower high stage compressor

- 1000-ton evaporative condenser

- Product transfer system

- Material handling and process platforms

- Process and clean-in-place systems

- Building air handling systems

- Product dust collector systems

- Building/process utilities (steam, water, air)

Client Background

Nestle is a multinational food and drink processing conglomerate and the largest food company in the world.